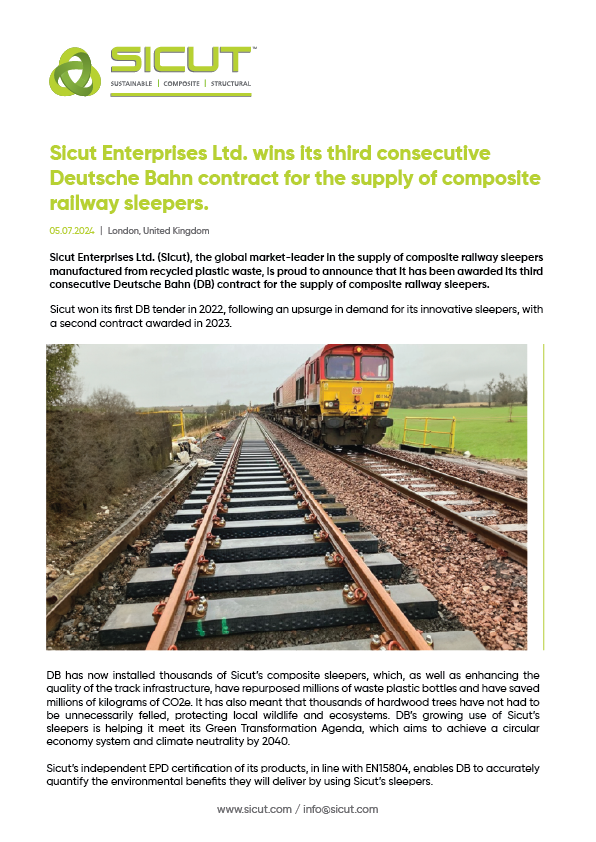

Sicut Enterprises Ltd. wins its third consecutive Deutsche Bahn contract for the supply of composite railway sleepers.

Sicut Enterprises Ltd. (Sicut), the global market-leader in the supply of composite railway sleepers manufactured from recycled plastic waste, is proud to announce that it has been awarded its third consecutive Deutsche Bahn (DB) contract for the supply of composite railway sleepers.

Sicut Sleepers Presentation to the Permanent Way Institute

Sicut CEO William Mainwaring and Network Rail’s Polly Morgan presented to the PWI about the use of recycled plastic sleepers and bearers in track infrastructure.

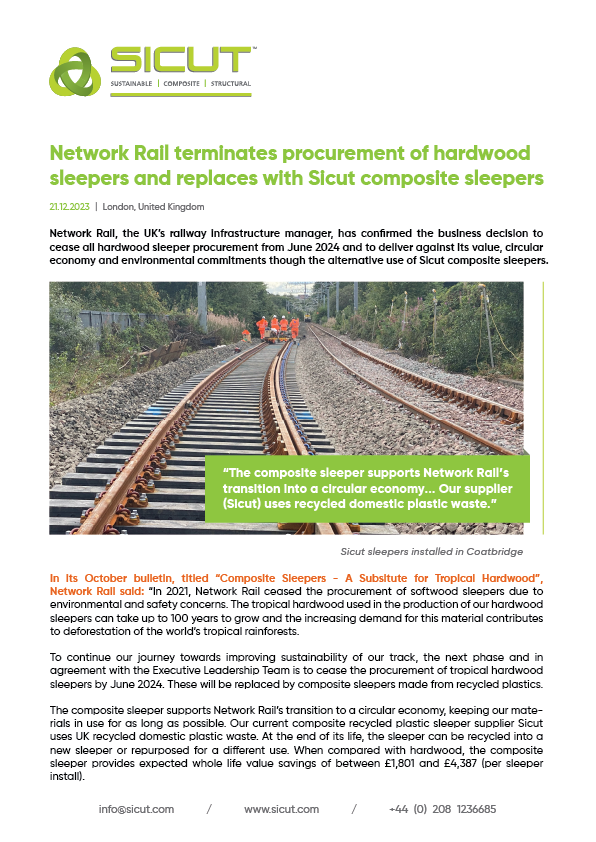

Sicut Sleepers save weight and help the environment

To reduce the load on a weight-restricted bridge, Network Rail has used plastic sleepers, manufactured from recycled materials, for the first time. Engineers recently installed the environmentally friendly technology across the Sherrington Viaduct, between Salisbury and Warminster in Wiltshire. Previously, track across the viaduct would have had to be fitted with wooden sleepers, as concrete would have been too heavy for the structure

Sicut Sleepers Make PWI Front Page News

Sicut Sleepers, developed by Rutgers University and exclusively licensed to Sicut, are front page news in the latest edition of the PWI Journal. An in-depth technical overview written by Rutgers Professor Tom Nosker and Arya Tewatia explain the origins, past developments and exciting new features incorporated into Sicut’s patented railway sleepers.